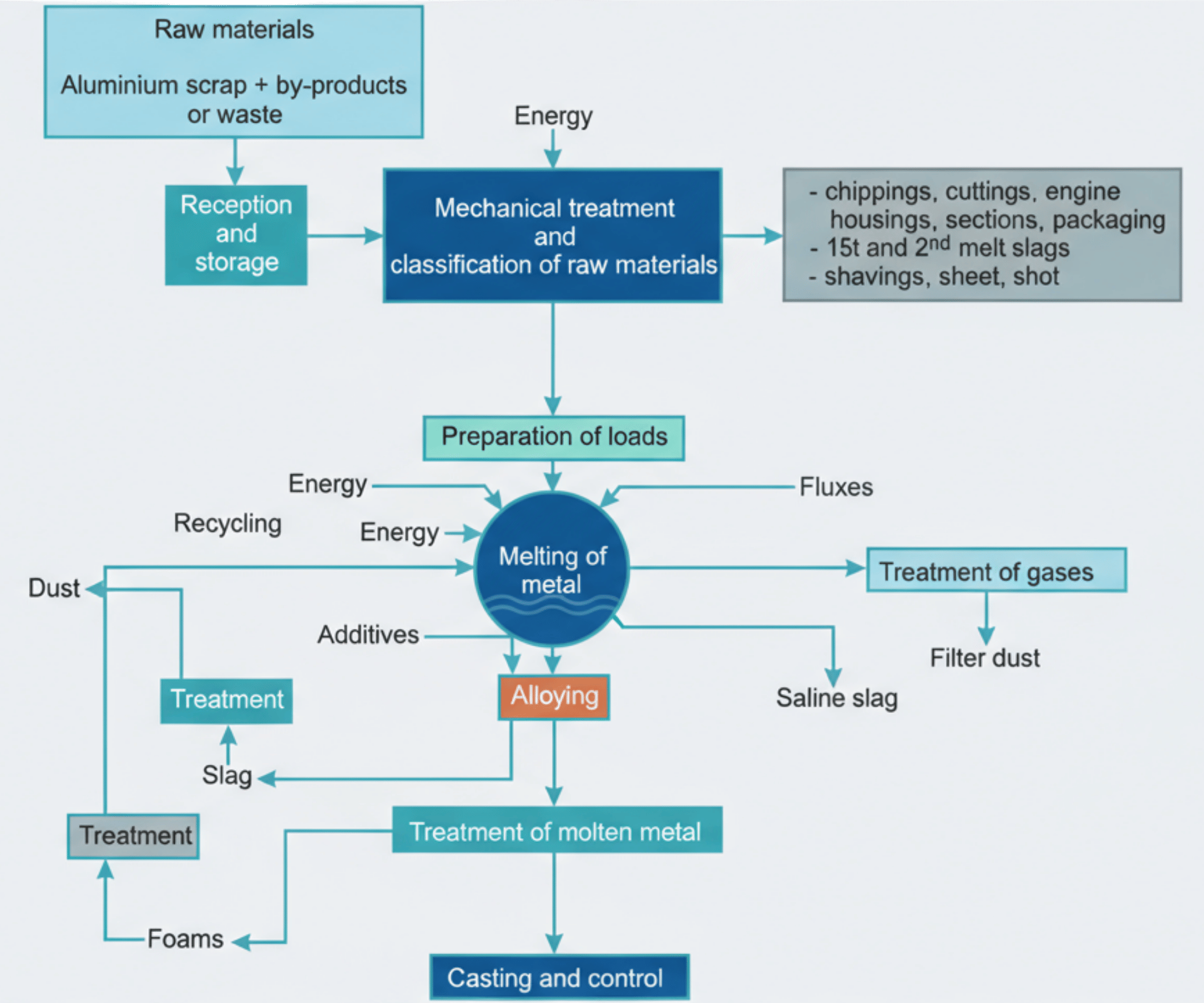

Process Description

The different amount of available metal and impurity in the Al scrap depend on the origin of the scrap itself. However, these characteristics can be changed before the melting process by means of specific treatments. The principal preliminary treatments applied to AL and CO scrap are hereafter discussed even if the objectives of all these processes are: increasing the bulk density, removing non-aluminum scrap, and reducing the impurity level.

Commission

The scrap occurs in a great variety of shapes and dimensions, so the combination is aimed to reduce this scatter. The objectives of commission are:

To obtain a proper distribution of scrap size, which is required by the subsequent steps;

- To increase the bulk density;

- To liberate components that form assemblies.

The commission can directly affect the melting rate with the scrap size but the main advantage is the possibility to remove undesired materials as rubber, magnesium, and zinc parts from the Al alloy.

Sorting

Aluminum alloys are used in several sectors and applications in combination with a lot of different materials, such as metals (steel, copper, zinc) or, in other cases, rubber, plastic, and glass. The Al scrap inevitably contains residuals of such materials that oblige refiners to properly screen the scrap before melting to enhance recycling efficiency and reduce the presence of impure elements.

Different types of scrap require various sorting methods and different results can be obtained. Thus, it is necessary to understand when the benefits outweigh the required investment.

Sorting casting and wrought Al alloys, for instance, allows the production of high quality wrought alloys that are actually not possible with mixed scrap, however, sorting technologies for this issue have high capital investments and high running costs.

Summarizes the main sorting technologies, highlighting both consolidated and innovative methods. The sorting technologies normally used for Al recycling aim to separate aluminum scrap from other materials, such as other metals or rubber. The research and the innovative technologies are now oriented not only to separate Al scrap, but to recognize the alloy group and, if possible, the specific Al alloy.

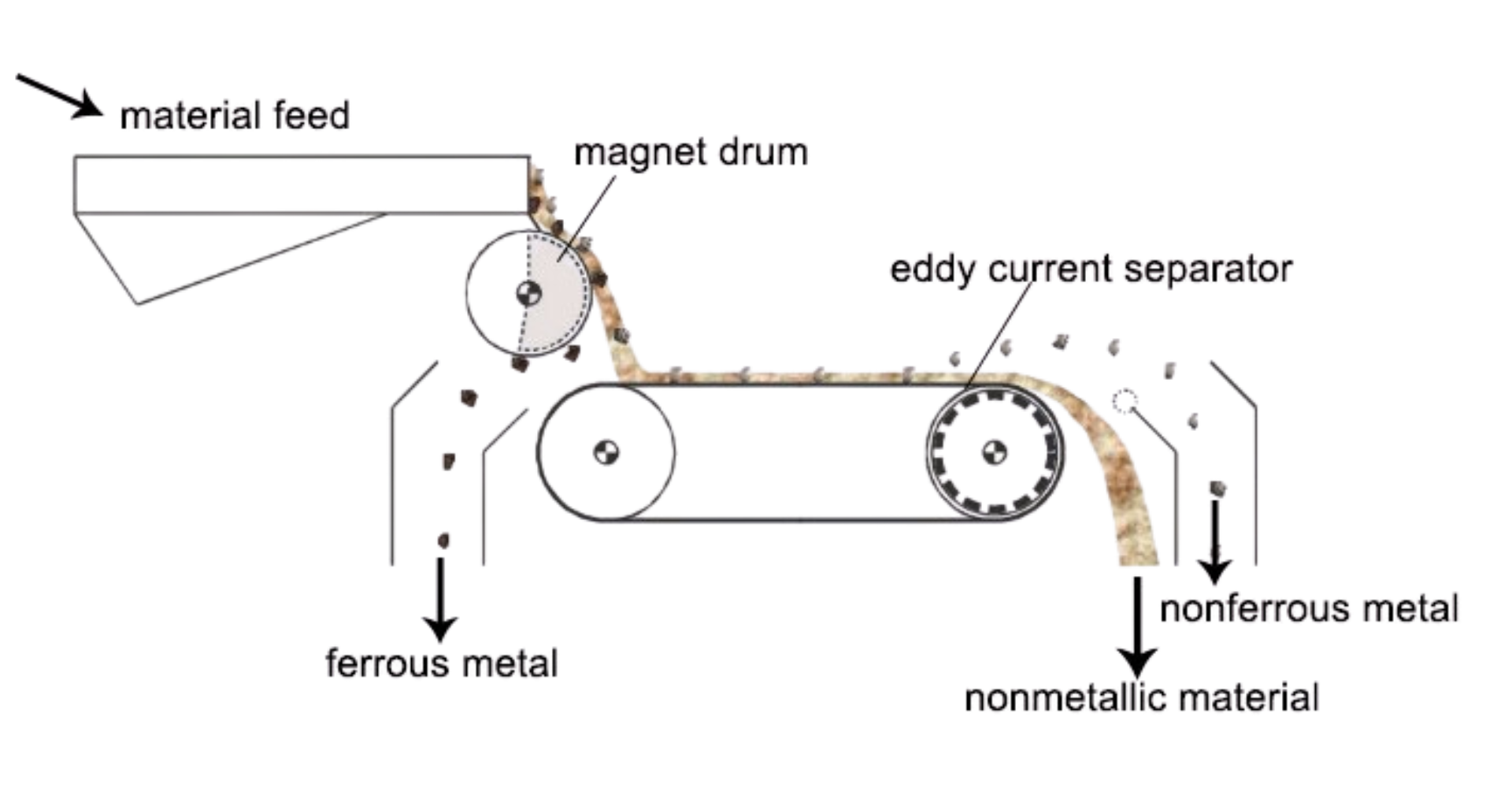

Magnetic Separation

Magnetic separation is one of the oldest forms of material separation and it has existed in the mineral processing industry since the early 1900s. It is a way to divide non-ferrous from ferrous components and it is extensively used in secondary Al industry. A wide variety of separators are available to perform this task. The most common are drum magnets and overhead belt magnets, which differ mainly for the plant layout. The scrap moves on a conveyor belt and it passes near a permanent NdFeB magnet. This generates a magnetic field responsible for an attractive force approaching ferromagnetic materials. Non-magnetic particles are unaffected by the magnet. Thus, the sorted scrap may still contain many non-magnetic contaminates.

The magnetic separation is widely used for sorting UBCs, this process provides the most compact and efficient method of sorting aluminum and steel cans. In general, two cycles of magnetic separation are planned for cleaning UBC scrap. Furthermore, most municipal recycling facilities (MRFs) also feature magnetic separation in their process.

Air Separator

Non-metallic materials are often light-weight materials such as plastics, rubbers and foams, and they can be separated using air classifier. Different technologies have been developed, but they differ for slightly dissimilar mechanisms. In a vertical air separation system, the recycled material stream is fed through a column with air blowing upwards. The heavy metals are collected at the bottom and the other materials are driven through various feeds further up.

Currently this sorting process is not widely used, however, in the future, most refiners will use some sort of air separation technique to create a mostly metallic scrap stream. The main drawback is the loss of lightweight metallic products, such as beverage cans and shredded pieces of a smaller size.

Hand Sorting

The practice of manual sorting is still considerably widespread. Manual sorting results in high purity levels, but because the labor cost is high this process serves only as a final check for quality control purposes. Manual sorting of material types is today already economically attractive in developing countries with low labor cost, such as China, India, and Brazil. It is estimated that workers in China can achieve accuracy up to 99% when sorting non-ferrous automotive shreds.

Thus, while manual sorting can distinguish aluminum from other materials such as copper and zinc, it is still a challenge to distinguish between different Al alloys. An exception is the possibility to identify casting versus wrought Al alloys based on their differing visual appearance.

Manual sorting is an obstacle to the development of new technologies when its results are cheaper than investments in mechanical sorting methods.

Innovative Sorting Solutions

The concentration of main alloying elements in the scrap can be identified by proper sensors for elemental composition and this enables the separation of alloy mixtures. Different solutions are available.

X-ray fluorescence (XRF) generates a collimated or diverging beam of X-rays to the surface of the material. The fluorescence photons generated are further detected by a solid-state photo cathode detector that produces a current pulse proportional in size to the energy of the incident X-ray photon. The produced energy is characteristic of the elemental emission line and the de-convoluted peak integral can be converted to the alloying element concentration by a suitable multivariate calibration procedure. Usually, XRF is carried out on the ground and suitable surfaces of the specimen are analyzed. At industrial scale, particle surfaces are not previously prepared and show random orientation and substantial distance to the detector, therefore, semi-quantitative results of the alloying elements’ concentration are expected from this technique. However, some industries have applied prototype systems to detect transition metal alloying elements in shredded Al scrap destined for wrought alloy applications.